Environmental Innovation

In 2023, the Company launched a specialized training program to enhance engineering innovation capabilities under the Engineering Improvement Program (EIP). This 9-month training initiative aimed to empower company engineers to demonstrate their potential and develop innovative solutions using Agile and Design Thinking methodologies. The program focused on enhancing employee competencies, fostering professional ethics in engineering, and providing business management perspectives through a combination of hands-on training, coaching, and innovation development projects. The initiative sought to improve operational efficiency, reduce costs, and create added business value, while also identifying high-potential engineers for future expert development The Company also launched the Quick Win Improvement 2023 project, aimed at encouraging employee participation in innovation development. The project’s success was established as a Corporate KPIs and a Common KPIs under knowledge management. This initiative served as an extension of the EIP training program, translating classroom knowledge into practical innovation concepts.

In 2024, the Company selected 3 outstanding innovation projects from the Quick Win Improvement 2023 initiative. These projects were chosen based on their impact on operational efficiency, cost-effectiveness, and environmental sustainability. The selected innovations are being implemented in a tangible and practical manner, as follows:

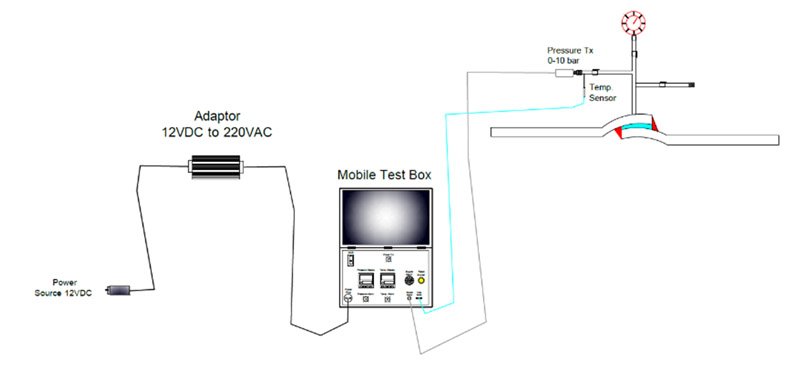

The AIR LEAK TEST KITS is an innovative solution for detecting leaks at the joint connections of raw water pipelines. This technology operates by measuring the air pressure injected into the space between weld joints, enabling precise geo-location of test points. It also allows for real-time monitoring and recording of test data. The measured values are displayed as pressure and temperature readings on an indicator within the monitoring device (mobile device). The system is also equipped with an alarm function that triggers an alert whenever measured values deviate from the predefined thresholds. This innovation reduces the workload for supervisors, eliminating the need for frequent travel to conduct inspections and record data. Additionally, contractors can proceed with work seamlessly without having to pause and wait for a supervisor to participate in testing. By implementing this technology, the company can shorten pipeline construction and maintenance timelines, enhance the efficiency of the water distribution network, and help reduce water loss in the pipeline system

Alignment with the Corporate’s Strategy:

S2.1 Enhancing efficiency and reducing costs

S3.1 Improving operations through technology and data utilization

Installation Areas and Implementation Plan:

The project is expected to be completed and the prototype device delivered within January 2025.

Project Outcomes:

- The Company reduced costs by approximately 500,000 Baht per project per year through the installation of the AIR LEAK TEST KITS, representing a 32.00% cost savings per project annually.

- The AIR LEAK TEST KITS innovation contributes to environmental sustainability by reducing fuel consumption required for inspection travel. Additionally, it enhances construction quality control, minimizing pipeline leaks and breakages, which in turn reduces water loss within the company’s distribution system.

The Company identified challenges related to installing monitoring and control systems within the raw water pipeline network, including corrosion mitigation systems for underground steel pipes. These systems are crucial for analyzing water distribution efficiency and optimizing pipeline maintenance. To address these challenges, the company developed the IoT Datalogger (EW Logger) as an alternative to traditional communication devices in customer stations. This innovation helps reduce construction costs associated with Supervisory Control and Data Acquisition (SCADA) communication systems at customer sites. Additionally, by developing in-house equipment, the Company can tailor functionality to meet specific operational needs while reducing procurement costs for sensor-based data logging equipment by more than 4 times.

Alignment with the Corporate’s Strategy:

S2.1 Enhancing efficiency and reducing costs

S2.2 Advancing toward Operations Automation

Installation Areas and Implementation Plan:

The Company has tested the system and installed prototype devices along its water pipeline network at 5 locations.

Project Outcomes:

- The IoT Datalogger (EW Logger) completely eliminates (100%) the need for customer station construction for installing control and monitoring systems within the raw water pipeline network.

- The Company reduced costs by approximately 150,000 Baht through the installation of the IoT Datalogger (EW Logger), achieving a 75.00% cost reduction compared to the construction of traditional monitoring stations along the pipeline network.

- The IoT Datalogger (EW Logger) contributes to environmental sustainability by reducing dust pollution from construction activities and lowering electricity consumption.

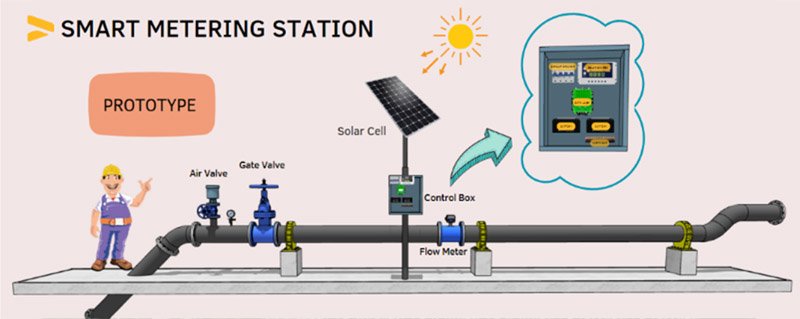

The Company has installed equipment for branch water pipelines supplying customers, including control cabinets and various monitoring devices. Therefore, the Company developed the Smart Metering innovation, a new communication system designed to replace traditional Programmable Logic Controller (PLC) systems, which are costly and complex. This innovation helps reduce the space required for installing control cabinets. It also equipped with a Flow Meter with a backup battery, reducing unnecessary equipment at monitoring stations. Additionally, the Smart Metering innovation consumes less electricity than traditional systems, enabling the use of solar energy as an alternative power source.

Alignment with the Corporate’s Strategy:

S1 Expanding revenue from new customer segments

S2 Enhancing efficiency and reducing costs

Installation Areas and Implementation Plan:

Raw Water Branch Pipeline Project – Nong Lalok Subdistrict, Ban Khai District, Rayong Province, serving 2 customers

Project Outcomes:

- The Smart Metering innovation in both projects reduces the construction area for branch pipeline stations by 10.00%.

- The Company reduced costs from the installation of Smart Metering system in both projects by approximately 1,000,000 Baht, representing a 27.00% cost reduction in the machinery control system.

- The use of solar energy in both projects generates 665.28 kWh/month, resulting in a reduction of greenhouse gas emissions by 332.57 kgCO2eq/year.

พื้นที่ก่อสร้าง Metering Station (ระบบเดิม)

พื้นที่ก่อสร้าง Smart Metering Pro (ระบบใหม่)