Risk Management in Procurement

The East Water Group has established a supplier management approach within its supply chain, with a commitment to developing suppliers and enhancing their capabilities to grow sustainably alongside the Group’s business operations. The East Water Group adheres to procurement regulations, practices, and its Supplier Code of Conduct, all of which incorporate key sustainability considerations. This reflects East Water Group’s clear intention and serves as a standard for its procurement process. In addition, the Group fosters supplier relationships through regular annual engagement activities that promote collaboration between the Company and its suppliers.

Procurement Policy

Guidelines for Supplier Risk Management

The East Water Group has established two criteria for evaluating procurement proposals to ensure fair competition and avoid selection based solely on price. This approach is designed to encourage suppliers to deliver the best quality products and services at fair prices to the Group. The two evaluation criteria are: Price and Price Performance.

The East Water Group has established criteria for selecting suppliers eligible to submit bids for the Company’s project procurement by creating an Approved Vendor List (AVL) categorized by types of work related to the quality management system in the raw water pumping and distribution process. This ensures that there are sufficient qualified suppliers to support the Company’s core operations. The work is divided into nine categories, with registration levels defined for each category. The criteria for vendor registration and classification are based on registered capital, past performance over the past 10 years, responsible personnel, and the availability of tools and machinery.

The Company also requires supplier performance evaluations upon project completion. For projects lasting more than one year, performance must be assessed annually until completion. Additionally, supplier registrations must be reviewed at least once every two years, providing suppliers the opportunity to submit updated information for reassessment and reclassification based on their current status. The Company reserves the right to remove any supplier from the Approved Vendor List (AVL) if their performance rating falls below the Company’s standards or based on other relevant disqualification criteria.

The supply chain risk analysis process consists of four processes as follows:

1.Consideration of Purchase and Procurement from Supplier

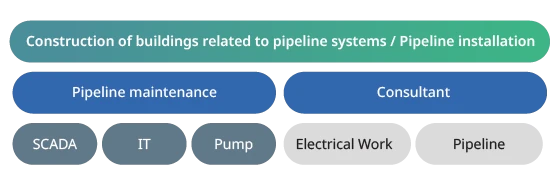

1.1 The Company has classified 9 types of suppliers who do business with the Company as follows:

- Different types of pipelines refer to water pipelines, measuring instruments, water meters, sluice gate, check valves, air valves, meters (only for main pipelines), with equipment sizes starting from 200 mm and above. These are classified into the following subcategories:

- 1.1 Pipe and equipment manufacturers

- 1.2 Pipe manufacturers with installation

- 1.3 Distributors and authorized dealers of pipes and equipment

- Pumps refer to raw water pumps with a capacity of 100 horsepower and above. These are classified into the following subcategories

- 2.1 Pump manufacturers

- 2.2 Pump distributors and authorized dealers

- 2.3 Contractors for procurement and installation of pumps

- Consultants refer to firms providing consulting services for building construction related to main pipeline systems, pipeline installation, pump systems, and main water transmission control systems (SCADA).

- Construction of buildings related to pipeline systems refers to the construction of the following types of buildings: pumping stations, water storage tanks, pressure-reducing tanks, and other structures associated with raw water transmission pipeline systems.

- SCADA refers to contractors responsible for the installation of water pumping and transmission control systems, including associated communication systems.

- Water pipeline installation refers to contractors responsible for the installation of raw water pipelines and/or the installation of customer water delivery stations and/or the repair of raw water transmission systems.

- Pipeline maintenance refers to the contracting of preventive maintenance services for main pipeline systems.

- Information technology systems refer to the contracting of services for the development and implementation of systems that utilize computers to manage, store, collect, and process data, as well as to generate reports for decision-making purposes.

- Electrical work refers to contractors responsible for the installation of high-voltage electrical systems, substations, and low-voltage electrical systems related to water pumping and transmission systems.

Suppliers in categories 3 through 9 are classified into different grading levels based on their respective work types (as referenced in the Work Instruction: Selection of Qualified Bidders)

1.2 Spend Analysis and Risk Assessment using the Supply Positioning Model.

2.Supplier Selection Criteria

In the case where the supplier is a new seller, contractor, or service provider

- 2.1 Legal Status of the Business: Supplier must provide proof of business registration, such as a company affidavit issued by the Ministry of Commerce (dated within the last 6 months), VAT registration (Por. Por. 20), or other relevant documents.

- 2.2 Product and Service Quality: The quality of goods and services will be evaluated in consultation with the requesting department and/or technical experts.

- 2.3 Reputation and Track Record: The supplier’s reputation and previous performance will be considered based on past clients, with possible reference checks from those who have purchased goods or received services.

- 2.4 ISO-Related Items: For goods or services specified in the ISO system documents, suppliers must submit the required ISO-related documents to register as an approved vendor, categorized by procurement type. This is to ensure that sellers, contractors, and service providers meet the Company’s quality standards and requirements.

- 2.5 Individual Service Providers: If the service provider is an individual, a copy of their national ID card (certified true copy) and work experience must be submitted.

- 2.6 Conflict of Interest for Design/Construction Supervisors: Service providers contracted for design or construction supervision must not also serve as contractors for the same project.

- 2.7 Ethical Business Conduct: Sellers, contractors, or service providers must operate their business with strict adherence to ethical principles, without engaging in corruption, bribery, or illegal activities. They must respect labor rights and treat workers fairly in accordance with international standards, taking into account environmental impact, social responsibility, and good governance (Environmental, Social, and Governance – ESG), which are key components of sustainable supply chain management.

In the case where the supplier is an existing or current seller, contractor, or service provider

The evaluation shall be based on criteria 2.1–2.7 above, with additional consideration of the following:

- 2.8 The price must be a competitive price in the market, and the evaluation shall consider value for money in relation to the quality of goods or services. Comparisons must be made based on the principle of equivalent quality standards.

- 2.9 Timeliness and compliance with sales terms and conditions.

- 2.10 After-sales service and warranty of goods or services.

3.Supplier Analysis and Classification

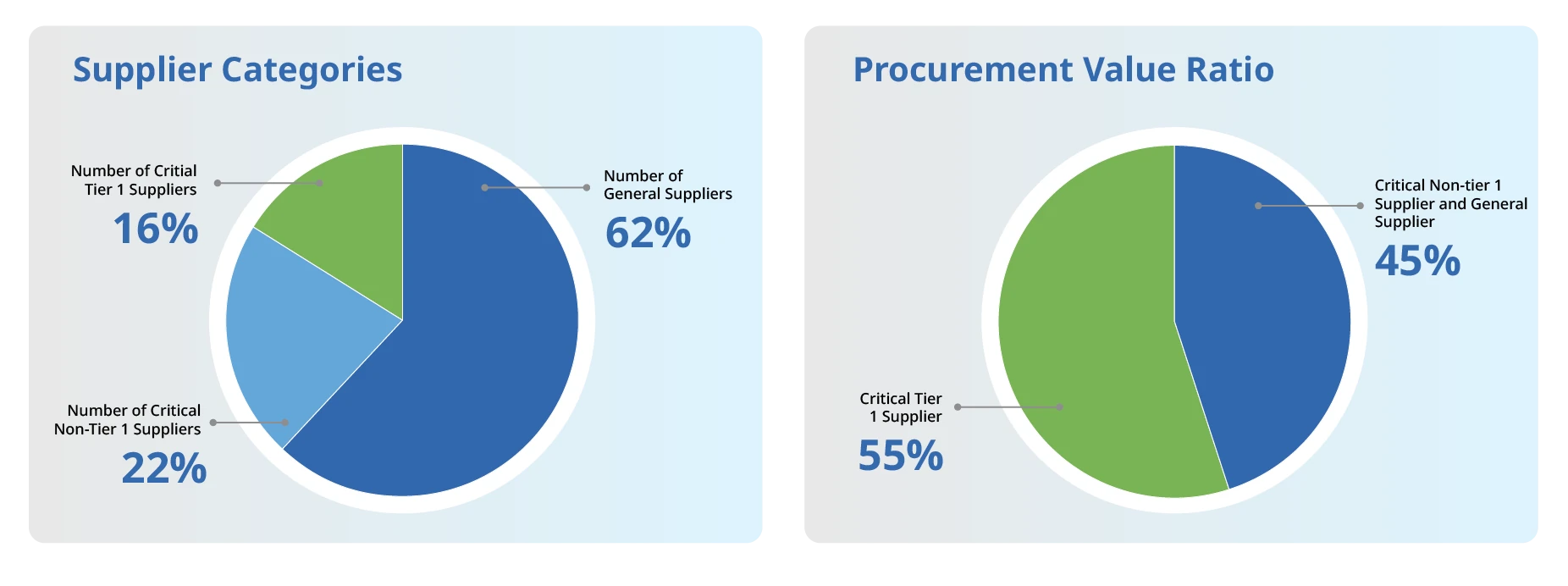

The process begins with collecting data on suppliers who have supplied goods or services related to the quality management system in the raw water pumping and distribution process during the past year (Tier 1), for the purpose of analyzing and identifying those that are critical to the Company (Critical Tier 1). The Company has therefore established criteria for classifying the importance of suppliers in alignment with their categories, as follows:

- - Critical Tier 1 Suppliers: Suppliers who supply goods or services directly to the Company and are registered on the Company’s approved vendor list.

- - Critical Non-Tier 1 Suppliers: Suppliers who supply goods or services to Critical Tier 1 Suppliers without having a direct business relationship with the Company.

| Evaluation Criteria Critical Tier 1 Suppliers |

Evaluation Criteria Critical Non-Tier 1 Suppliers |

|---|---|

| 1. Purchase value 2. Purchase frequency 3. Capability as listed in the Approved Vendor List (AVL) |

1. Supply of goods or components that are critical to the Company’s core procurement, or goods/services with Company-specified technical requirements 2. Goods or services with high procurement value |

Payment Period for Suppliers in 2024

- The Company has set a payment term of 30 days for its suppliers.

- The actual average payment period to suppliers in 2024 was 10 days.

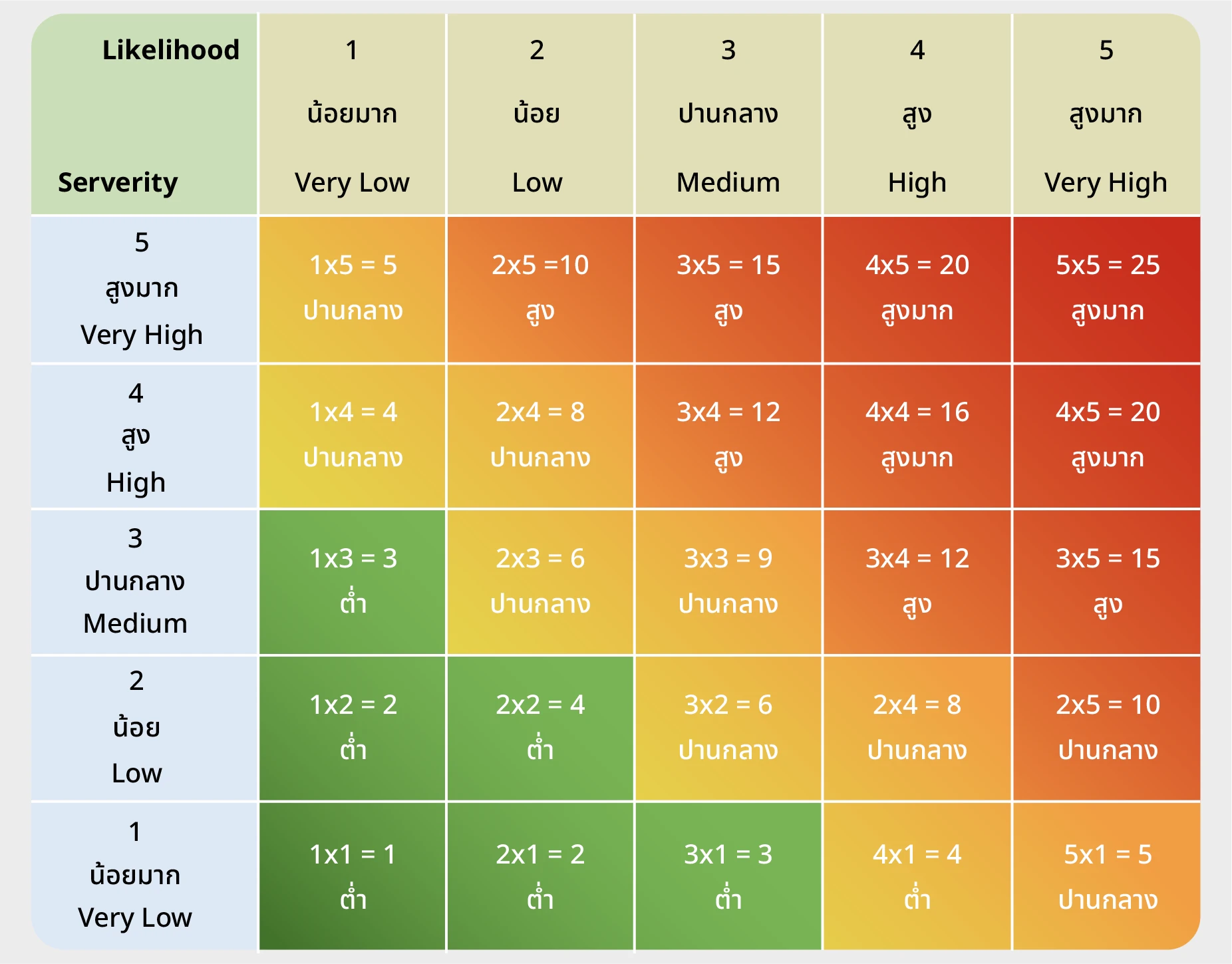

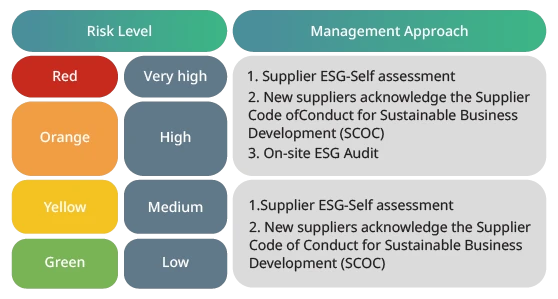

ESG Risk Assessment of Supplier

The Company is committed to conducting business with its suppliers in accordance with the Supplier Code of Conduct for Sustainable Business Development (SCOC), which covers environmental, social, and governance (ESG) issues. The ESG risk assessment process begins by classifying suppliers based on their involvement in the Company’s core operations. This involves identifying potential risk events that may occur and affect business activities, assessed from two perspectives: likelihood and impact. Both qualitative and quantitative evaluation methods are applied in combination to identify high-risk supplier groups and to develop appropriate risk management approaches aimed at reducing both the likelihood and impact of risks across each vendor group.

4.1 ESG Risk Assessment Criteria for Suppliers (Based on the Organization’s Risk Assessment Criteria)

- 4.1.1 LIKELIHOOD

ESG control measures and operations of suppliers, including incidents that occurred in the past three years, are considered based on suppliers’ self-assessment, with reference to the organization’s risk assessment criteria. - 4.1.2 IMPACT

Consider the potential impacts in the areas of environment, society, and governance, with reference to the organization’s risk assessment criteria.

ESG Issues Considered in the ESG Risk Assessment of Suppliers

| Environmental Issues | Social Issues | Governance Issues |

|---|---|---|

| 1. Water management (water use and wastewater management) 2. Energy management 3. Climate change and greenhouse gas management 4. Waste and hazardous waste management 5. Chemical and hazardous material management 6. Biodiversity 7. Other environmental management issues (noise and air pollution) |

1. Human rights 2. Labor practices 3. Safety, occupational Health, and working environment 4. Impacts on community quality of life and community engagement |

1. Compliance with the Supplier Code of Conduct 2. Compliance with applicable laws, regulations, and requirements 3. Ethical business conduct and transparent, accountable operations 4. Anti-corruption practices 5. Risk management 6. Intellectual property protection and confidentiality 7.Conflict of interest 8. Risk from dependency on a limited number of suppliers |

ESG Risk Assessment Results of Suppliers

Critical Tier 1 Suppliers were assessed, accounting for 60% of all critical suppliers

The ESG risk assessment revealed that all ESG-related risk issues were at a low level.