Electricity Consumption and Energy Conservation Measures

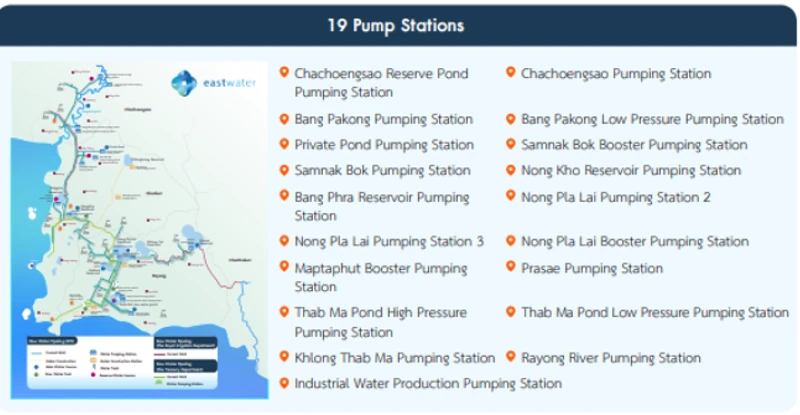

Electricity is a key driver of the water pumping and distribution system. It is also a main cost of the Company. Electricity consumption is directly correlated with the volume of water pumped through the Company’s Water Grid covering 19 pumping stations and 55 power sub-stations and metering stations. Hence, the Company is committed to ensuring the reliability of its pumping and distribution system by setting a goal of no disruptions to the water distribution from the main water grid. Nevertheless, according to the Company’s requirements, there is an eight-hour interval for stopping the water distribution for maintenance purposes. However, for machines or equipment with critical duties (Class A), there is no time interval for stopping the operations.

Realizing the importance of efficient energy consumption, the Company continued to implement energy conservation projects for its water pumping and distribution system and office buildings to save energy and improve energy consumption efficiency organization-wide through the Energy Management Working Group. This not only helped manage costs and expenses for the organization, but also served to reduce the “global warming” problem. The energy conservation efforts covered the following operating sites:

1. pumping stations registered as controlled factories, including: Nong Pla Lai Pumping Stations (2-3), Bang Pakong Pumping Station / Bang Pakong Low-Pressure Pumping Station, Chachoengsao Pumping Station, Bang Phra Reservoir Pumping Station, Samnak Bok Booster Pumping Station, Prasae Pumping Station, Nong Kho Pumping Station, Thab Ma Pond High Pressure Pumping Station/Thab Ma Pond Low Pressure Pumping Station, Khlong Tabma Pumping Station, Rayong River Pumping Station, and Industrial Water Production Pumping Station. Additionally, 2 more stations are under the registration process as controlled factories: Nong Pla Lai Booster Pumping Station, Maptaphut Booster Pumping Station.

2. 1 controlled building

i.e., Head Office Building. Each year’s energy conservation target will be set up based on previous year’s energy conservation performance evaluation results. The new target shall be further reduction in the energy consumption at organizational, production or service, and device levels. The factors to be considered shall include levels of energy loss realized and improvement possibilities

3. 55 power sub-stations

4. 11 entities of tap water production station of UU PCL.

Summary of Operations of Energy Consumption Efficiency Enhancement Projects in 2024

Electricity-Saving Measures for 2024

| Remises | Projects | Before Improvement (kWh/y) |

After Improvement (kWh/y) |

Electricity saving (kWh/y) |

|---|---|---|---|---|

| Head Office | 1. Managing the Chiller Plant system with the Chiller Plant Management System (CPMS) | 623,562.54 | 589,332.05 | 34,230.49 |

| 2. Cleaning condensers of chiller units | 512,573.16 | 497,195.96 | 15,377.20 | |

| 3. Replacing water pumps with high-efficiency models | 86,629.40 | 63,534.92 | 23,094.48 | |

| 4. Enhancing cooling tower heat dissipation | 34,122.61 | 17,061.30 | 17,061.31 | |

| 5. Maintaining split-type air conditioning units | 205,059.29 | 198,907.51 | 6,151.78 | |

| 6. Adjusting the set point temperature of the MDB room air conditioning system for optimal usage | 53,666.93 | 34,883.51 | 18,783.42 | |

| 7. Eliminating the use of ventilation fans in the MDB air-conditioned room | 9,082.49 | 0 | 9,082.49 | |

| Total | 1,524,696.42 | 1,400,915.25 | 123,781.17 | |

| CO2 emissions (kg-CO2eq) | 762,195.74 | 700,317.53 | Reduction in CO2 emissions 61,878.21 kg-CO2eq |

|

| Operating sites Nong Pla Lai Pumping Stations (2-3, Chachoengsao Pumping Station, Bang Pakong Pumping Station, Prasae Pumping Station, Thab Ma Pond Total High Pressure Pumping Station, Bang Phra Reservoir Pumping Station, Samnak Bok Booster Pumping Station, Khlong Thab Ma Pumping Station, Rayong River Pumping Station and Industrial Water Production Pumping Station. one station, Nong Kho Pumping Station, has been exempted from Implementing mandatory energy conservation measures as required by law |

1. Maintenance of air conditioning systems. | 1,245,508.82 | 1,195,519.88 | 49,988.94 |

| 2. Replacing air conditioning units with high-efficiency models. | 68,720.50 | 22,426.48 | 46,294.01 | |

| Total | 1,314,299.32 | 1,217,946.36 | 96,282.95 | |

| CO2 emissions (kg-CO2eq) | 656,983.24 | 608,851.39 | Reduction in CO2 emissions 48,166.84 kg-CO2eq |

Measures of Solar Energy as an Alternative to Electricity for 2022-2024

| The Company | Type | Operation Period (๋Jan - Dec) | |||

|---|---|---|---|---|---|

| 2021 | 2022 | 2023 | 2024 | ||

| The Company | |||||

| Head Office | SOLAR ROOFTOP SYSTEM (kWh/y) | 11,893.70 | 26,955.00 | 25,621.00 | 25,482.00 |

| Operation area | 0 | 0 | 0 | 6,970.58 | |

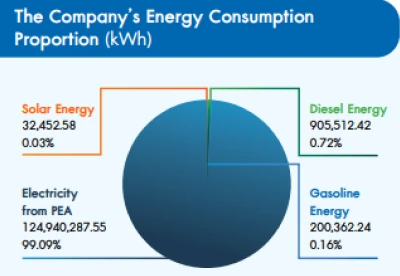

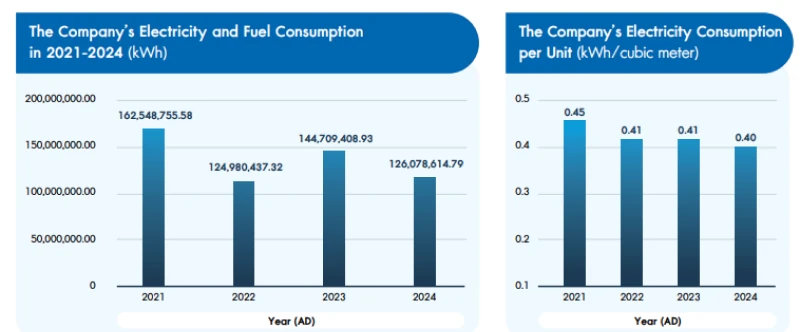

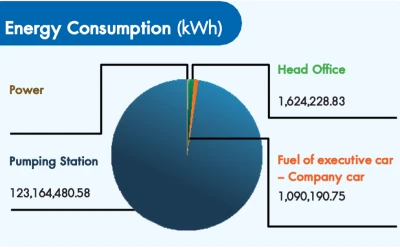

In summary, the Company’s electricity and fuel consumption in 2024 in 3 main forms i.e., electric energy, solar energy, fuel energy (diesel and gasoline) accounted for 126,078,614.79 kWh. The calculation was based on:

- Pumping Station 123,164,480.58 kWh.

- East Water Building Head Office 1,624,228.83 kWh.

- Power Sub-stations along the pipeline 199,714.63 kWh.

- Fuel of executive car – Company car 108,776.39 Liters, equivalent to 3,921,549.45 mega Joules or 1,090,190.75 kWh.

In 2024, the economic slowdown in the industrial sector led to a decrease in customer production capacity, resulting in lower water demand compared to 2023. As a result, the company’s electricity and fuel consumption decreased by 21,630,794.14 kWh, representing a 14.95% reduction in total energy consumption from 2023.

Additionally, the company has initiated a project to enhance the capacity of the water pipeline network to accommodate future water demand. However, it has maintained energy efficiency in water pumping, with energy consumption at 0.40 kWh/cubic meter, energy consumption per unit of water decreased by 2.44% from 2023.