Safety, Occupational Health, and Working Environment

(Disclosure 403-1, 403-2, 403-7, 403-8, 403-9, 403-10:2018)

The East Water Group has developed and announced operational regulations,

an occupational health, safety, and workplace environment management manual, and other related documents to ensure compliance with the Occupational Health and Safety Management System standard (ISO 45001:2018). Additionally, the East Water Group has set the goal of achieving “zero workplace accident” to create a safe working environment, enhance the quality of work life for employees, suppliers, and contractors, and ensure compliance with relevant laws and standards.

In 2024, the East Water Group has revised the Work Instruction document to be convenience for the usage, and improved the performance record document to be in line with nature of actual operation and be in line with relevant laws.

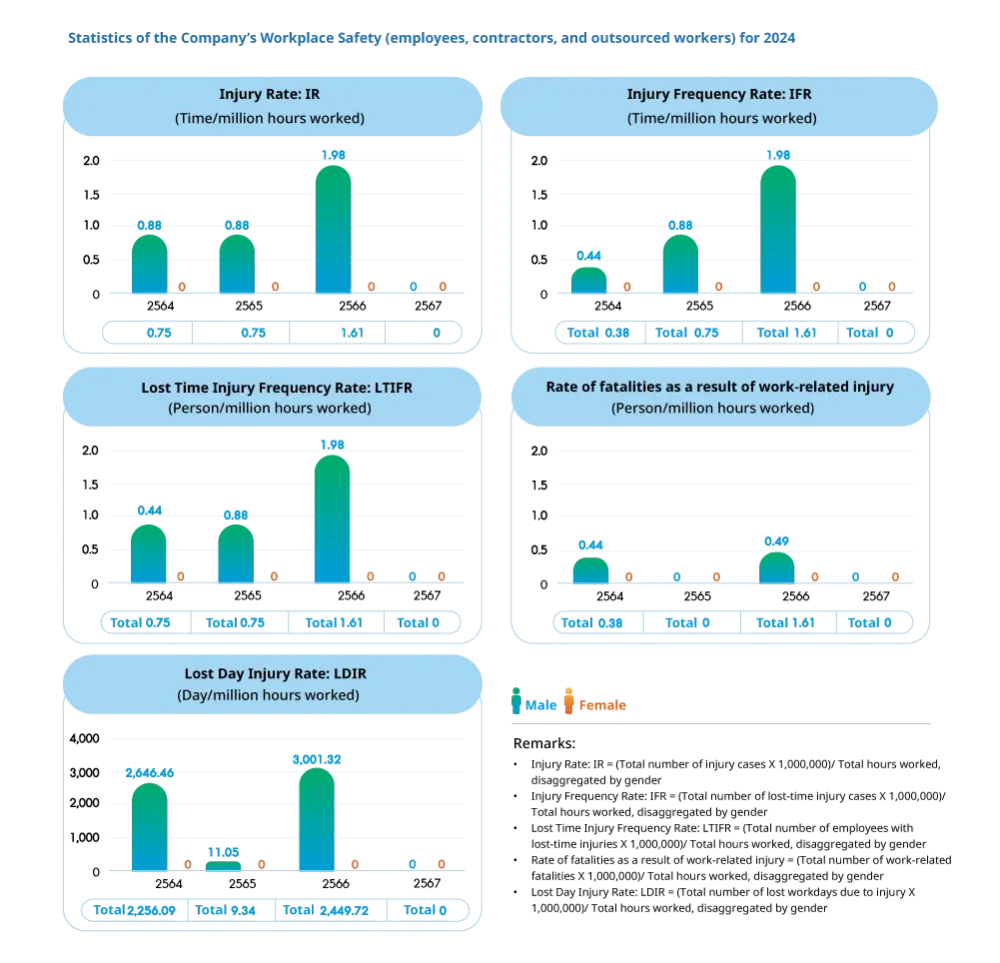

In 2024, there were no reported accidents involving employees, contractors, or outsourced personnel within the Group.

Statistics of the Company’s Workplace Safety (employees, contractors, and outsourced workers) for 2024:

In 2024, the East Water Group had 3 Working Groups (Committee) on Safety, Occupational Health, and Working Environment i.e., Working Group of the Head Office, Working Group of the Operating Area, and Working Group of UU PCL., to thoroughly oversee the operations in the respective areas under responsibilities. They hold meeting every month and consist of members as follows: (Disclosure 403-4: 2018)

Roles and responsibilities of the 3 working groups cover:

Safety Activities

(Disclosure 403-3, 403-6, 403-7, 403-10:2018)

East Water undertook a series of safety activities as follows:

Results of the assessment to identify threats to health and assess the health risks of employees, contractors, and outsourced workers can be summarized as follows:

1.1 Employees: It was found that there are threats to health such as light, noise, UV rays, blue light, chemicals, working posture with computer, psychosocial, biological (communicable diseases), heat, dust, and security threats, etc. In addition, the Company has organized additional health examination programs according to risk factors such as hearing test, visual inspection, etc. In 2024, the Company’s employees did not find the incidence of occupational diseases.

1.2 Contractors and Outsourced workers : The Company required that its contractors and outsourced workers have an annual health check to monitor chronic communicable diseases, diabetes, high blood pressure, abnormal blood lipid, that may affect cardiovascular disease, as we monitoring abnormalities from work such as vision loss, hearing loss from loud noise, etc. Especially working in hazardous areas, contractors and outsourced workers who enter the area must have health check-up results in accordance with law and strictly follow it. In 2024, contractors and outsourced workers of the Company did not find the incidence of occupational diseases

A monthly journal on safety, health, and environment (SHE News) was distributed to the employees to share news and information as well as create awareness of safety, good health, and environmental care.

A training plan on safety, occupational health, and working environment was established for each target group of employees. There were 21 training courses facilitated in the past year (Disclosure 403-5: 2018) as follows:

The East Water Group has been implementing the Health Promotion and Office Syndrome Prevention Program for the 4th consecutive year, aiming to prevent work-related illnesses commonly found among office workers, such as back pain, neck and shoulder pain, and headaches. These issues often result from improper posture and prolonged screen time without changing positions. The program includes the following activities:

4.1 Physical massage activities to relieve office syndrome symptoms

4.2 The training activity provided employees with knowledge under the topic “Say Goodbye to Neck, Shoulder, and Back Pain from Office Syndrome with Simple Massage Tips for Office Workers.”

The East Water Group hosted an online Safety Month Event at the East Water Building. The goals and objectives were to instill awareness of work safety in employees to know how to work safely and can prevent dangers and accidents correctly. It was also to create unity within the organization and to create a happy working atmosphere, Happy Work Place, and employees who pay attention to safety will have good health and reduce work-related stress. It was also to convey the executives’ intention to place importance on work safety to employees. There were 4 activities namely:

5.1 Organizing exhibition to disseminate safety knowledge and Activities to answer questions on knowledge of safety, occupational health, and environment through Yammer, Line, E-mail and Poster.

5.2 Safety Talk on the topic of “Cybersecurity and Information Technology Crime Prevention”by Inspector of Criminal Records Sub-division 5, Criminal Records Division, Office of Police Forensic Science.

5.3 The educational game activity on basic safety, occupational health, and environmental awareness serving as a refresher to reinforce knowledge and understanding while promoting awareness among executives and employees at all levels about the importance of workplace safety, focusing on minimizing workplace accidents.

5.4 The “Chill Afternoon with Safety” activity providing an opportunity for employees to engage in discussions and exchange knowledge with professional safety officers, featuring expert speakers who are occupational safety professionals from the EWG.

Through these activities, employees have reviewed their knowledge and understanding of safety, occupational health, and environment. It also encouraged both executives and employees at all levels to recognize the importance of workplace safety while focusing on reducing workplace accidents. It also promotes better health, while employee work happily and reduce work stress.

The activity focused on creating safety behaviors for employees leading to the creation and improvement of the organization’s safety culture. The activity was organized with employees in the Company’s operating areas. In addition, APT’s of all employees have been extended into a quarterly APT’s program to set a good example and make employees more aware of the benefits of hazard search activity to create employee engagement. In the work of each day, regular inspections were planned, starting from the operational method, machine conditions, chemicals, and work-related environment as well as the operator. There was a system to follow up and take corrective action in a timely manner, making employees aware about safety including identifying unsafe behaviors leading to preventive measures before accidents occur.

In 2024, the goals and KPIs have been determined. Executives and all employees of the operation function must participate in such activity on an ongoing basis. According to the assessment, it was found that 98.82% of employees in the operation function were continuously involved in the activities and achieved the set goals, with 1.18% of employees in the operational function failed to meet the set goals.

East Water places great importance on and actively promotes a safety-oriented organizational culture. As part of this commitment, it has implemented the Behavior-Based Safety (BBS) Project and the Building Safety, Health, and Environment (SHE) Mindset Initiative to establish a mental framework or attitude that influences feelings, actions, and behaviors, ultimately driving positive outcomes. The objective is to instill in employees a strong mindset towards Safety (S), Health (H), and Environment (E). Executives emphasize fostering a safety culture that stems from employees’ safety attitudes and awareness, which are fundamental principles of good safety behavior. The activities were divided into 5 key components:

7.1 Conduct training on “Building SHE in the Organization” to enhance employees’ understanding and foster a SHE mindset at all levels.

7.2 Appoint a committee for the Behavior-Based Safety (BBS) initiative at the headquarters.

7.3 Conduct a survey on the SHE mindset within the organization.

7.4 Provide training on “Volunteer for Behavior-Based Safety” to employee representatives from each department.

7.5 Implement Job Safety Analysis (JSA) activities to observe and ensure safe work practices.

East Water has continued its Mental Health Promotion Project for the second consecutive year, emphasizing the importance of mental health as a key factor in assessing employee happiness at work when working under the same organization. By fostering a Happy Workplace environment, the initiative encourages employees to prioritize both physical and mental well-being, enabling them to adapt, solve problems, and perform their tasks effectively. The program aims to enhance self-perception, emotional stability, and social adaptability in an ever-changing environment. As part of this initiative, the company provides access to psychiatric or psychological counseling services.

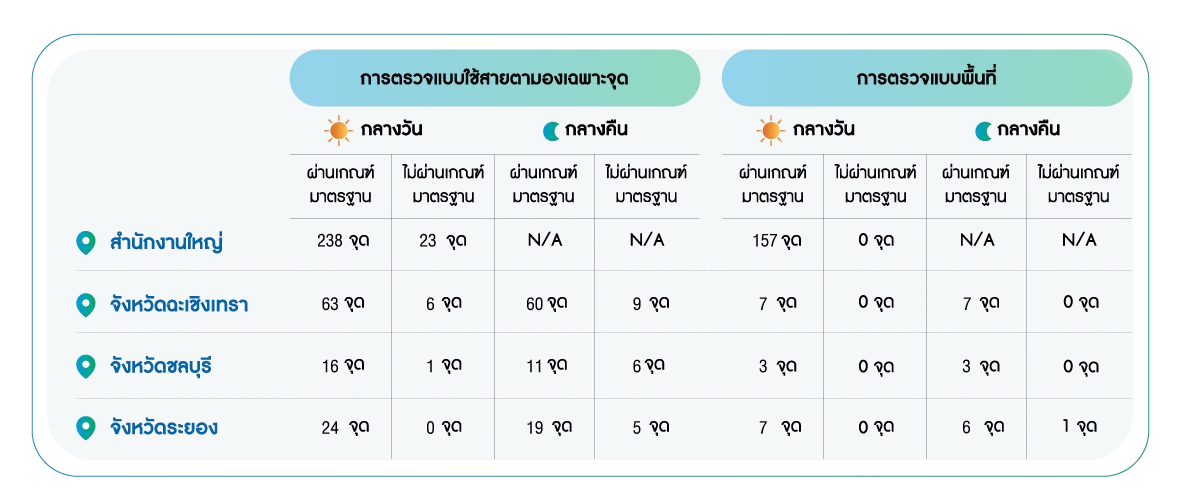

9.1 Lighting Measurement: The Company conducted 1 inspection of lighting in the workplace as follows:

Following an inspection of workplace lighting conditions, the Company implemented improvements by installing LED High Bay lighting systems to ensure full coverage of the work area. After completing the installation, a subsequent light measurement was conducted, confirming that all areas met the required standard levels.

9.2 Working equipment: The Company has checked the working equipment everyday including Motor, Pump, Accessory Pump, Valve system, Electrical system, Fire Alarm system, Control Scada/Instrument, flowmeter, online water quality meter, etc. It was found that they are in normal condition and ready to use.

9.3 Fire protection equipment: The Company has arranged for the provision of fire protection equipment by supplying hand-held fire extinguishers, installing a fire alarm system, preparing fire escape routes, installing hand-held fire extinguishers, along with regularly inspecting all kinds of safety equipment as categorized below:

- FM_Por_400-017 RV.00 - Inspection form of hand-held fire extinguisher.

- FM_Por_400-018 RV.00 - Inspection form for portable gas detector.

- FM_Por_400-020 RV.00 - Inspection form for emergency lights and fire exit signs.

- FM_Por_400-031 RV.00 - Inspection form for manual fire alarm device.

- FM_Por_400-032 RV.00 - Inspection form for automatic fire extinguishing equipment.

9.4 Personal protective equipment: The Company provided employees with personal protective equipment (PPE) that meets standards. Before receiving the equipment, the Company requires the employees to study details of the use of PPE and how to take care of it such as safety shoes, safety hat, earmuffs, safety glasses, and leather gloves.

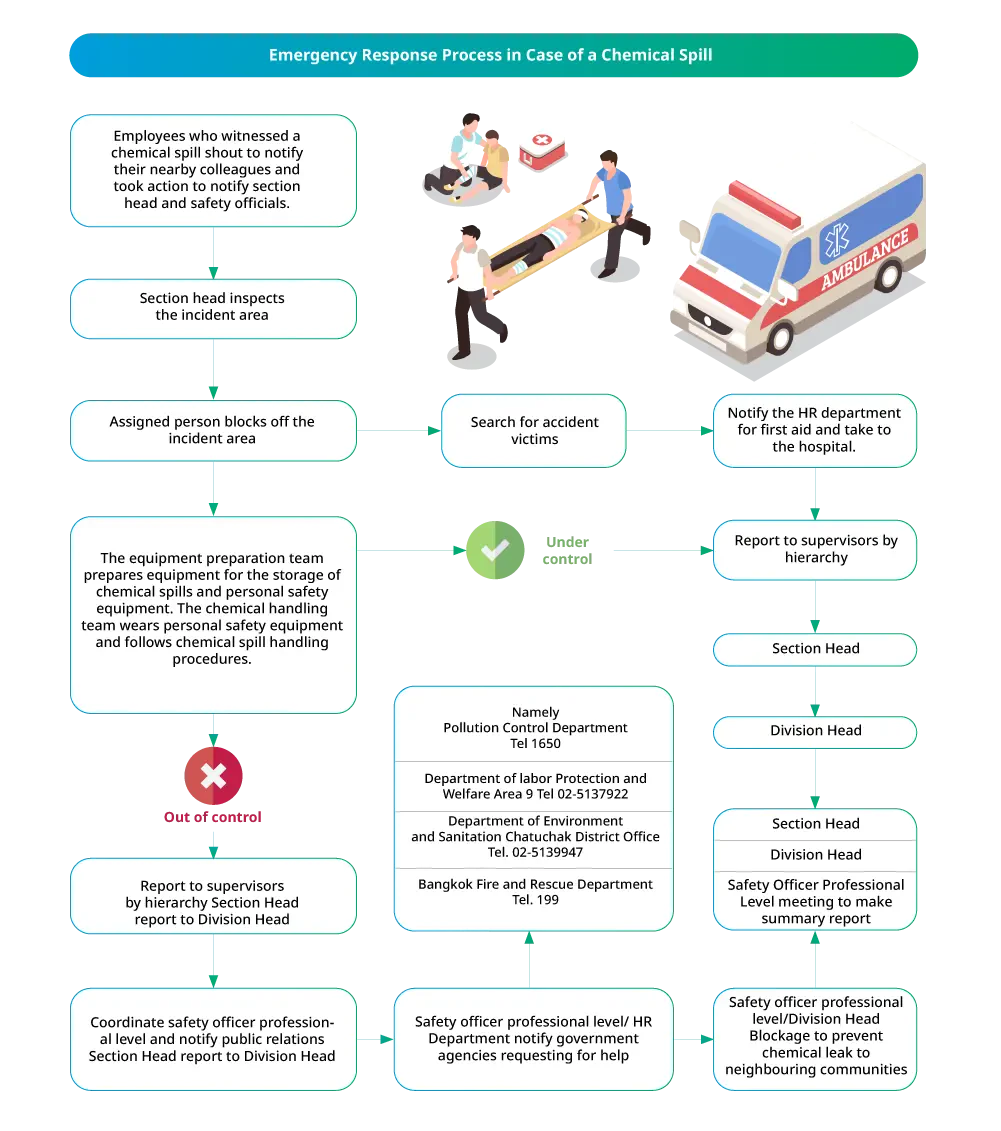

9.5 Leakage of hazardous substances: Chemical used by the Company is only Sodium Hypochlorite. The Company has established a chemical storage area in accordance with Ministerial Regulations prescribing standards for management and operation of safety, occupational health, and working environment regarding hazardous chemicals

B.E. 2556 (2013). The Company has inspected storage area for leakage chemicals monthly. There is a report of a list of hazardous chemicals with details of the safety information of hazardous chemicals (Sor Or.1), a report of measurement and analysis of the concentration of hazardous chemicals in the atmosphere of the workplace and the hazardous chemicals storage area (Sor Or.3), and declaration form of producers, importers, exporters, or persons in possession of hazardous substances under he responsibility of the Department of Industrial Works (Wor Or. Or Kor 7) as required by law. (Disclosure 305-6)

In 2024, no chemical spills were found, and a contractor was hired to inspect airborne emissions to confirm that, in addition to physical inspection, there was no leakage (airborne) that could not be physically detected. There is also an annual chemical spill rehearsal with relevant parties. (Disclosure 306-3)

Emergency Management

The Company placed emergency management as one of its priorities. To prepare for any incidents and mitigate any potential impact on the Company’s employees and properties, the Company took relevant actions in 2024 as follows:

1. The Company has revised the Business Continuity Management (BCM) Manual and updated the Business Continuity Planning (BCP) while also conducting a business continuity drill at the Head Office at East Water Building by simulating a fire incident, and in the operating area simulating a scenario involving a rupture and leakage of the raw water reservoir, leading to flooding on roads, agricultural areas, and nearby communities.

The Company tested the completeness of the BCP as well as the knowledge and understanding of functional duties and responsibilities. The Company ensured the readiness of its information system and operating systems, alternate workplace, and the communications between the employees working from home, internal units, and external agencies

In addition, Crisis Management Plan (CMP) has been created to ensure preparedness for managing unexpected incidents or temporary situations to be able to cope with various situations that may occur in the future to reduce damage that may occur to the Company and stakeholders. This included the preparation of a Crisis Communication Plan to achieve effective and fast communication

2. The Company’s annual firefighting and evacuation drills were divided into 2 areas as follows:

- Head Office area, East Water Building The drills were divided into 2 sessions i.e., firefighting and evacuation drill at night and during business hours

- The operating area drills were conducted at stations and offices covering Rayong, Chonburi, and Chachoengsao provinces

These were to prepare for evacuation practice, fire protection system testing in case of an incident, with government agencies, fire stations, police stations, hospitals, training agencies, and neighboring buildings cooperated and supported the drills, in which the objectives of the drills were accomplished.

3.The Company’s annual chemical spill emergency drills were conducted to prepare for hazardous chemical or fuel spill operations, as well as waste management in accordance with the Ministerial Regulations.